Decarbonising maritime

Shipping is one of the most important sectors of the global economy, transporting about 80% of the world’s trade by volume. However, it is also a major source of greenhouse gas (GHG) emissions, accounting for about 3% of the total global emissions. To address the urgent challenge of climate change, the International Maritime Organization (IMO) has set an ambitious target to reduce the GHG emissions from international shipping by at least 50% by 2050, compared to 2008 levels, and to phase them out as soon as possible in this century.

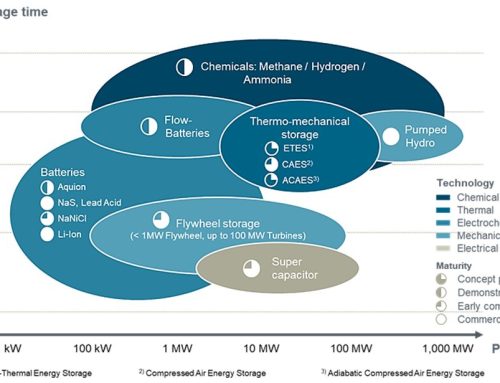

However, achieving this goal is not easy, as shipping faces many technical and economic barriers to decarbonisation. One of the main challenges is the lack of suitable alternative fuels that can replace the conventional fossil fuels used by most ships today. Electrification, which is widely adopted in light-duty vehicles, is not feasible for most ships due to the high energy density and long range requirements. Therefore, there is a need to explore other options that can provide clean and sustainable energy for shipping.

Why ammonia?

Among the various candidates for future zero-carbon fuels, green ammonia (NH3) has emerged as one of the most promising ones. Ammonia is a compound of nitrogen and hydrogen that can be produced from renewable sources such as wind, solar or hydro power. This makes green ammonia a zero-carbon fuel from production to end-use, unlike other fuels that may still emit CO2 during their life cycle. Ammonia also has the highest energy density among other zero-carbon alternatives like hydrogen and doesn’t require cryogenic temperatures (below -150oC) or high pressure for storage and transportation.

However, ammonia also has some drawbacks that need to be addressed before it can be widely adopted as a shipping fuel. One of the main challenges is the safety and environmental impact of ammonia, which can pose risks to human health and marine ecosystems. Another challenge is the engine technology and performance of ammonia-fuelled ships, which may require significant modifications and innovations to achieve high efficiency and low emissions. Moreover, there are regulatory and policy barriers that need to be overcome to enable the uptake and acceptance of ammonia as a shipping fuel.

MariNH3

MariNH3 is a consortium of researchers from Nottingham, Birmingham, Brighton and Cardiff universities, as well as 23 industry partners who are working to tackle these challenges and accelerate the development and deployment of ammonia-fuelled ships. The research is focusing on three major themes, namely Acceptance, Fundamentals and Application.

Using ammonia in an internal combustion engine

Researchers at University of Nottingham, within the Powertrain Research Centre (PRC), are focusing on understanding the fundamentals and application of ammonia in internal combustion engines.

Since ammonia can be used in both compression ignition (diesel) and spark ignition (petrol) engines, two engine test cells have been adapted at the PRC for ammonia research. The compression ignition/dual fuel research is carried out in a marine derivative of Volvo Penta D-8 engine while the spark ignition investigations are carried out in a single cylinder derivative of a MAHLE Research engine. In addition to the conventional combustion systems, research is also carried out on novel retrofittable solutions like MAHLE Jet ignition (MJI) and Hydrogen Assisted Ammonia Jet Ignition (HAAJI) in these engines.

MAHLE single cylinder engine at University of Nottingham, retrofitted to operate on ammonia, hydrogen or a combination of both.

Promising results – spark ignition and jet ignition

Both engines were successfully run on ammonia earlier this year, with the spark ignition engine capable of operating on 100% ammonia over a wide range of speed and load points. The results from these test ammonia powered engines can achieve higher efficiency and reduced emissions (NOx) at low speed (1000-2000 rpm) operating conditions compared to pure E10 operation.

One major challenge identified from these initial tests were significant amount of unburned ammonia in the exhaust, the results from these tests were presented at the MariNH3 conference held in June 2023 and are available here.

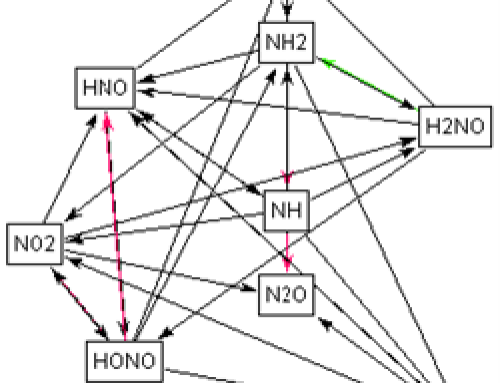

Following these investigations, further work has been carried out to understand the viability of active and passive jet ignition systems using hydrogen as an auxiliary fuel. The results show considerable improvements in combustion and NOx emissions with active jet ignition even when the hydrogen energy fraction was close to 1%. Further investigations are necessary to determine the true potential of this system.

Future work on combustion, performance and emissions

With the viability of HAAJI successfully investigated, the next phase of the research will focus in understanding the impact of various parameters like pre-chamber volume, nozzle size and composition of fuel air mixture in the pre-chamber on the combustion, performance and emissions produced by the system. The work will also focus on developing methodologies that aim at reducing both NOx and unburned ammonia without sacrificing the performance and efficiency of engines.

In conclusion – ammonia is a viable fuel for shipping

It is evident from the completed research that ammonia is a viable zero carbon fuel for the maritime sector, it can be applied to both existing and future IC engines with minimal changes and can operate at similar efficiency to fossil fuel counterparts.

The major challenges to deal with the application of ammonia in IC engines are to with unburned ammonia and NOx emissions. However, since ammonia is already used to reduce NOx in aftertreatment systems a complete elimination of unburned ammonia is not necessary for adoption of it as a fuel.